Product Introduction

Product Introduction

BOPP Laminated Woven Bag is a type of bag produced by laminating a printed BOPP film to woven polypropylene fabric. These bags meet the high-stiffness requirement for the automatic packaging production line. The BOPP Laminated Woven Bag combines the strength and durability of the woven fabric with the high-quality printing and texture characteristics of the BOPP film. The bags have high exterior printing quality and are suitable for a wide range of applications. They can be used to package various merchandise and are an excellent choice for a variety of packaging needs. The eco-friendly bags are made solely from polypropylene material and can be directly recycled, increasing the sustainability and value of the product.

Produced by laminating a printed film to woven fabric, our BOPP woven bags offer high external printing quality and are puncture-resistant, waterproof, dirt-resistant, and recyclable. These bags are perfect for adding value to your product and can be used to package a wide variety of merchandise.

We commit towards providing sustainable packaging solutions to our valued customers. With our bags, you can ensure that your product is eco-friendly and satisfy your customers' desire to reduce their environmental footprint. Trust us to provide you with quality packaging solutions that meet industry standards.

Specification

Specification

Single-Sided / Double-Sided BOPP Laminated Woven Bag

50~110 cm

35~75 cm

1~7 colors

≦ 50 kg

Customizing Options

Customizing Options

Top and Bottom:

The top and bottom of the BOPP Laminated Woven Bag are typically sealed by heat sealing or sewing. Heat sealing involves heating and pressing the top and bottom of the bag together to create a seal. Sewing is achieved by stitching the edges of the bag together. Additionally, features such as heat-shrink labels and zippers can be added to the top and bottom of the bag.

Sides:

The sides of the BOPP Laminated Woven Bag are created through either sewing or bonding of the fabric edges to the BOPP film. Sewing involves stitching the woven fabric together, while bonding involves bonding the BOPP film to the woven fabric using an adhesive. Additional features such as side pleats, gussets, or handles can be added to the sides of the bag.

The production of BOPP Laminated Woven Bags can be customized according to different packaging needs and design requirements. Various sizes, shapes, colors, and have different functions to meet the requirements of different products.

Some of the uses of BOPP Bags include

Some of the uses of BOPP Bags include

Other products

Other products

Product Introduction

Product Introduction

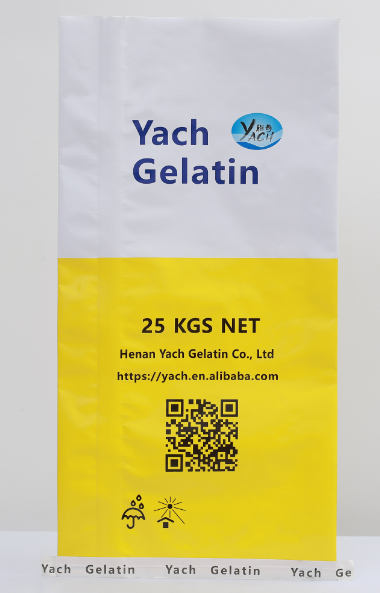

PP woven bags are a type of versatile packaging and carrying solution for various items made of polypropylene fabric. The PP fabric used in these bags is a combination of tightly woven warp and weft threads, providing an economical yet durable material for the bags. PP woven bags are well-known for their strength, lightweight feel, and flexibility, which allows them to be used in many different environments and for a range of applications.

One of the key benefits of PP woven bags is their durability; they can withstand heavy weights and impacts without tearing or breaking. PP woven bagsare commonly used in industries such as agriculture, industrial packaging, construction, transportation, and storage. They are also ideal for situations where hygiene and cleanliness are essential, such as food packaging and medical facilities.

PP woven bags come in all shapes and sizes, depending on the customer's requirements. They can be customized in terms of opacity, color, and finish. Additionally, logos and information can be added to the bags to promote brand recognition or provide essential product information.

In conclusion, PP woven bags are an excellent, cost-effective option for packaging and carrying goods. Their strength, lightweight feel, and versatility make them suitable for various applications, making them an excellent choice for businesses looking for a reliable and flexible packaging solution.

Specification

Specification

Single-Sided / Double-Sided BOPP Laminated Woven Bag

50~110 cm

35~75 cm

1~7 colors

≦ 50 kg

Customizing Options

Customizing Options

PP Woven Bag is made of polypropylene woven fabric and BOPP film. The top and bottom of the bag are mainly sealed by heat sealing or sewing, and the sides are created through either sewing or bonding of the fabric edges to the BOPP film. The bag can also be equipped with various functional features such as zippers and handles according to different packaging needs and design requirements.

Some of the uses of Bags include

Some of the uses of Bags include

Other products

Other products

Product Introduction

Product Introduction

PP woven kraft paper bags are a popular packaging option for many businesses due to their durability, strength, and versatility. They are made by bonding fine woven polypropylene fabric to kraft paper using heat and pressure, resulting in a bag that is both strong and flexible. It is widely used in several industries such as construction, agriculture, and animal feed.

One of the most significant benefits of PP woven kraft paper bags is that they can be customized to meet specific business needs. The bags can be printed with logos, text, and graphics, which make them an ideal choice for businesses looking to promote a brand or product. This helps businesses to stand out and reach new customers by creating a unique identity.

These bags are the ideal packaging solution for a wide variety of products, including pet food, fertilizers, chemicals, and construction materials. They are also extensively used in the agricultural industry to store and transport crops such as grains, fruits, and vegetables. Because of the bags' high strength and flexibility, they can withstand the rigors of long-distance transport or rough handling during storage or shipping.

Another key benefit of PP woven kraft paper bags is that they are environmentally friendly and can be recycled. They are made of 100% recyclable materials, making them an eco-friendly alternative to other non-biodegradable materials.

Overall, these bags are an affordable and reliable packaging solution that offers several benefits. They are highly customizable, environmentally friendly and can withstand harsh conditions, providing businesses with a cost-effective option for their packaging needs. If you are looking for a long-lasting, eco-friendly, and cost-effective packaging solution for your business, PP woven kraft paper bags are the answer. with quality packaging solutions that meet industry standards.

Specification

Specification

Single-Sided / Double-Sided BOPP Laminated Woven Bag

50~110 cm

35~75 cm

1~7 colors

≦ 50 kg

Customizing Options

Customizing Options

Top:

1.Crease: Fold the PP woven sheet according to the desired width and length to form a crease, which serves as the top edge of the bag.

2.Heat sealing: Place two folded PP woven sheets facing each other and use a heat sealer to heat-seal them to form the sealed top of the bag.

3.Sewing: Place two folded PP woven sheets facing each other and use a sewing machine to stitch them to form the sealed top of the bag.

Bottom:

1.Bottom sealing: Fold the PP woven sheet according to the desired width and length to form a crease, which serves as the bottom edge of the bag. Use a heat sealer or sewing machine to seal the bottom and form a sealed bottom of the bag.

2.Bottom reinforcing piece: Add a reinforcing piece, such as another PP woven sheet or thick cardboard, to the bottom of the PP woven sheet to increase the carrying capacity and durability of the bag.

Some of the uses of BOPP Bags include

Some of the uses of BOPP Bags include

Other products

Other products

Product Introduction

Product Introduction

PP Woven Roll Fabric is an environmentally friendly packaging material made from recycled polypropylene with minimal impact on the environment. This fabric has multiple practical properties, including excellent durability, weightlessness, and ease of maneuverability. Because it can be recycled and reused, it helps reduce resource waste. PP woven fabric is wide-ranging in its applications that include various bags, packaging materials, fabric coverings, and waterproof materials.

The PP Braided Coil is composed of two interwoven PP braided sheets sewn or connected by a thermal bonding technique, which forms a sealed coil. The high load-bearing capacity of PP Braided Coil is due to its durability and ruggedness, making it less susceptible to damage or breaking. It is also waterproof, moisture-proof, and dust-proof, rendering it useful in both dry and wet environments. It provides safety, security, and protection for various items.

Compared to other fabrics and materials, the PP woven material is outstanding. It is environmentally friendly, reduces pollution to the environment, and is more consistent with people's environmental protection concepts. Additionally, its numerous practical characteristics make it highly versatile for varied applications. In industrial settings, it is very suitable for packing and safeguarding different items while in everyday life, it can be used for making diverse bags, such as shopping and school bags. PP woven fabric is the go-to packaging material for various uses.

In conclusion, PP woven coil is a high-quality, environmentally friendly, and durable fabric with many practical properties. It provides excellent solutions for both life and industrial production, gaining recognition and acceptance from a growing number of users. If you have not yet used PP woven coil, try it now, and be amazed by its versatility and convenience.

Specification

Specification

35~110 cm

customization

Customizing Options

Customizing Options

Some of the uses of BOPP Bags include

Some of the uses of BOPP Bags include

Other products

Other products